Pharmaceutical Grade HPMC

Hydroxypropyl methyl cellulose (HPMC) is a non-ionic cellulose ether. It is odorless, tasteless, off white powder, can be dissolved in water and forms transparent viscous solution. HPMC is widely used in pharmaceutical grade HPMC capsules, food and other applications.

The viscosity of pharmaceutical grade HPMC is usually between 5-100mpa.s.

KAPPTAI can provide samples to customers for testing.

- Description

- Inquiry

Description

Provide High-quality Pharmaceutical Grade HPMC Raw Materials

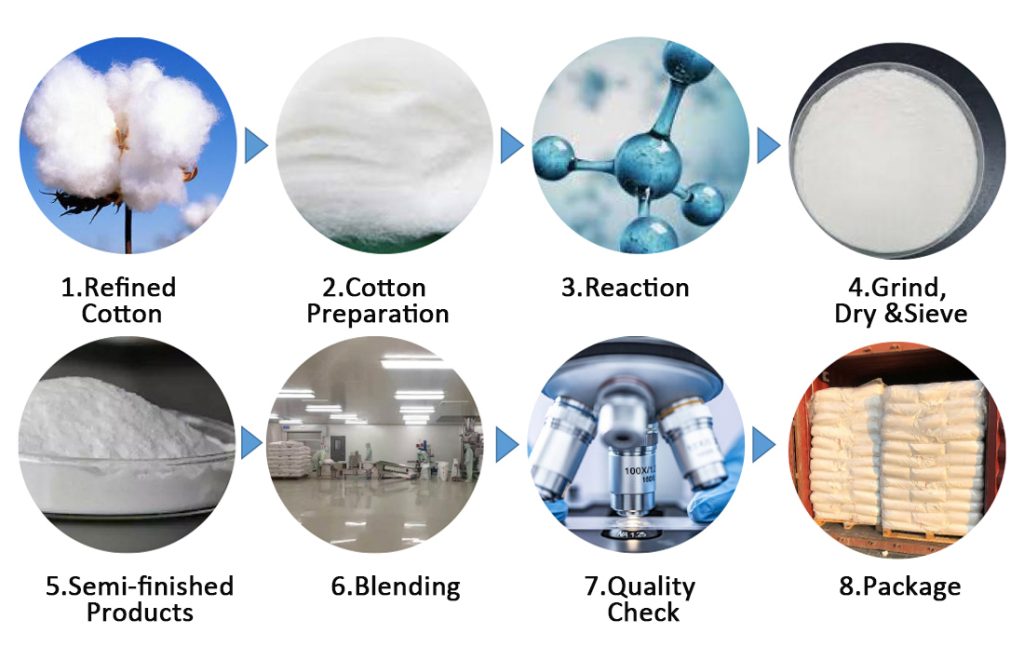

HPMC Pharmaceutical Grade for HPMC Capsules.This product of pharmaceutical grade HPMC selects highly pure cotton cellulose as raw material and is made by special etherification under alkaline conditions. The whole process is completed under GMP conditions and automatic monitoring, without any active ingredients such as animal organs and grease. pharmaceutical grade HPMC viscosity will be different according to different uses, the medicinal is usually 5Mpa.s. Buildings are usually 5000-200,000.

As a white powder, pharmaceutical grade HPMC has the function of thickening and retaining moisture. It is usually used in hard capsules, food, etc., and the most common one is as the main ingredient of vegetarian capsules.For pharmaceutical grade HPMC, we have complete certificates, ISO9001, ISO14001, ISO45000, MUI HALAL, FSSC22000, to meet the import requirements of customers, and the annual production capacity of 30,000 tons, strong supply capacity, to meet customer procurement needs, delivery time 7-20 days , fast delivery ability, to ensure the stable production of customers.

At present, we have exported to the United States, Canada, Southeast Asia and other countries and regions, and established contacts with many powerful pharmaceutical companies and food companies.

Pharmaceutical industry: coating materials; Membrane material; Rate-controlled polymer materials for sustained-release preparations; Stabilizing agent; Suspended aid; Tablet adhesive.

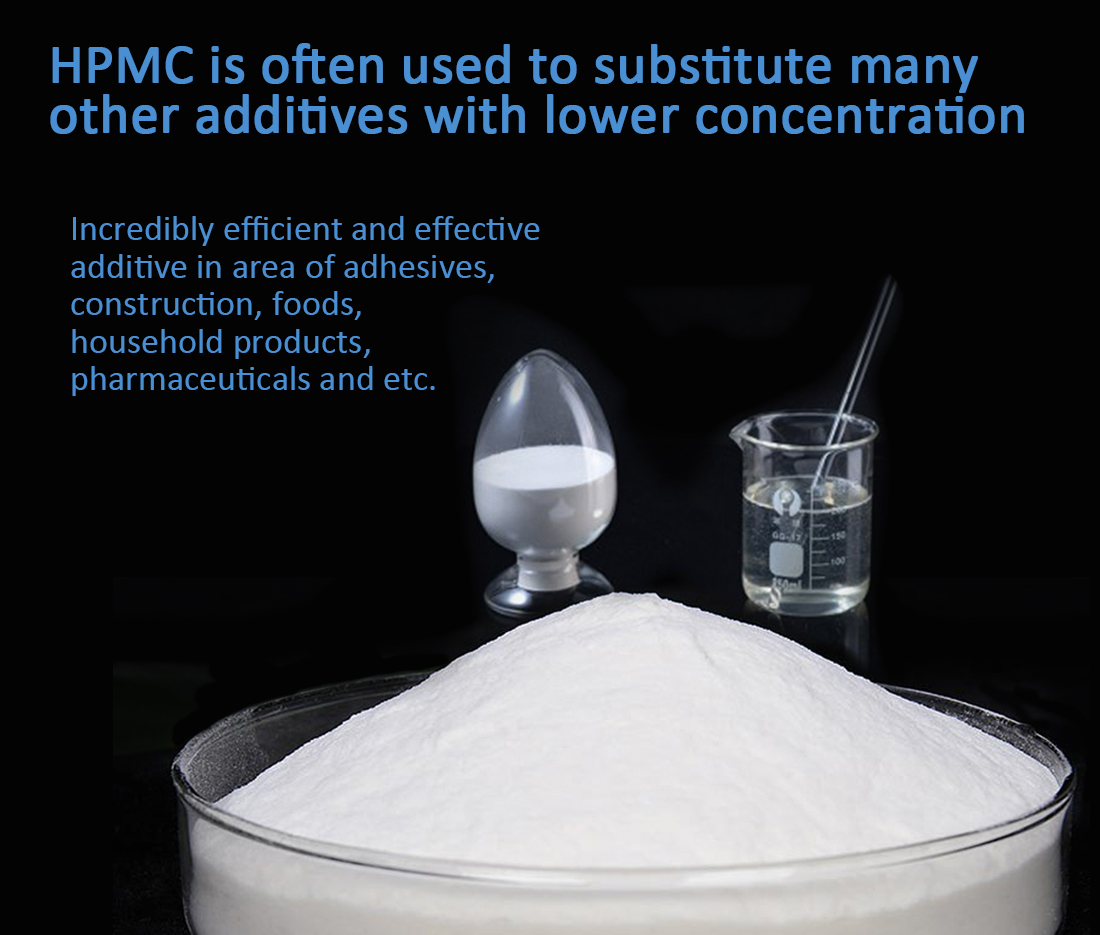

HPMC is divided into Pharmaceutical Grade and construction grade. The medicinal grade is mainly used in the production of vegetarian capsules. This product is a multifunctional pharmaceutical excipient, can be used as thickening agent, dispersant, emulsifier and film forming agent. In oral solid preparation as film coating, adhesive, etc., can significantly improve the stability and solubility of drugs, and can enhance the waterproof tablet. It can also be used as suspension aid for suspension, as matrix material for ophthalmic preparation, as skeleton material for hydrophilic gel framework sustained release tablets and gastric floating tablets, etc.

HPMC and other polymer compounds or colloidal drug combination, can prevent water or ethanol from transparent water colloidal drug separation, with water retention effect. pharmaceutical grade HPMC can also be used as thickener, emulsifier and other applications in food industry, daily chemical industry to improve the rheological properties of products. In addition, gelatin capsules update the replacement product plant capsules of the main raw material is also pharmaceutical grade HPMC.

Physical properties:

This product is non-ionic cellulose ether, the appearance is white powder, odorless tasteless, soluble in water and most polar organic solvents (such as dichloroethane) and appropriate proportion of ethanol/water, propyl alcohol/water, etc. Aqueous solution has surface activity, high transparency and stable performance.

HPMC has the properties of thermal gel, the product water solution is heated to form gel precipitation, and then dissolved after cooling, different specifications of the product gel temperature is different. Solubility changes with the viscosity, the lower the viscosity, the greater the solubility, different specifications of HPMC has a certain difference in its properties, pharmaceutical grade HPMC in water is not affected by PH value. Particle size: 100 mesh pass rate is greater than 100%. Bulk density: 0.25-0.70g/ (usually about 0.5g/), specific gravity 1.26-1.31. Discoloration temperature: 190-200℃, carbonization temperature: 280-300℃. Surface tension: 42-56dyn/cm in 2% aqueous solution.

With the increase of methoxyl content, the gel point decreased, the water solubility increased, and the surface activity also increased. HPMC has the characteristics of thickening, salting, low ash content, PH stability, water retention, dimensional stability, excellent film forming and extensive resistance to enzyme, dispersity and cohesiveness.